Research topic 3 & 4: Pre and post plant nutrition and pest management

Trial number 03-SEQ-04

Boom spraying is a common practice employed in pineapple production internationally. It is used for pesticide application to manage diseases, insect pests and weeds and for post-plant fertiliser applications.

Sectional and variable rate control on the boom sprayer for more precise application of chemicals and fertilisers is attracting interest due to its economic and environmental benefits.

The main aim of automated sectional and variable rate control systems is to reduce over-spray of crop inputs by turning off boom sections as they pass over previously treated areas or areas that don’t need spraying. Some systems have the capability to only spray within pre-loaded GPS field boundaries or boundaries recorded by the operator during an initial pass around the field of the block using manual entry of GPS co-ordinates. This map-based function ensures that boom sections are automatically turned off when passing over areas outside cropped regions of the field. An added benefit of this boundary mapping feature is that some systems allow the operator to map interior field areas to prevent application into environmentally sensitive areas such as grassed waterways or stream buffers.

Another important requirement for automatic boom sectional control systems is to maintain application rates by regulating flow to the boom. Current spray rate controllers attempt to compensate for changes in speed which control pump output based on feedback from a sensor continually scanning the ground. Similarly, sectional control systems require an integrated spray rate controller to adjust total flow to compensate for boom sections as they are switched on or off.

All auto-sectional control systems use GPS to work out the precise point at which boomsprayer sections should be switched on and off to minimise overspray and avoid any misses. There are several spraying systems available, either as options on new sprayers or as retrofits to existing sprayers.

OBJECTIVE

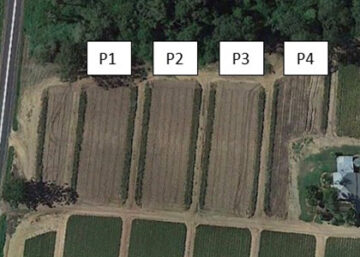

The primary objective is to adapt, develop and integrate variable and sectional rate boomspray application equipment and aerial imagery into a pineapple production system.

- To adapt, develop and construct a variable and sectional rate boomspray.

- To integrate Global Positioning Systems (GPS) technology into a pineapple boomspray operation to enable the variable and sectional rate boomspray to function.

- To integrate imagery into pineapple operations and utilise the data for better agronomic decision making.