Research topic 3: Pre and post initiation nutrition management

Trial number 03-WB-05

Fertilisers and pesticides contribute significantly to the cost of pineapple production. With growing concerns about their potential environmental impact and increasing costs, using these products efficiently and effectively has never been more important. Traditionally, hauled trailers with large tanks and extended booms fitted with hydraulic nozzles are used to apply fertiliser and pesticide.

The key to efficient boom spray operations is to maximize application to the target area and minimize application to non-target areas.

The design and calibration of the sprayer needs to consider crop parameters such as type and area of the plant canopy, area of plant leaf, height of the crop and the product being applied.

Precision agriculture seeks to use new technologies to increase crop yields and profitability while lowering the levels of traditional inputs needed to grow them. Precision spraying can be defined as targeted spraying using specific crop information and efficiently applying pesticides and fertilisers to the target area.

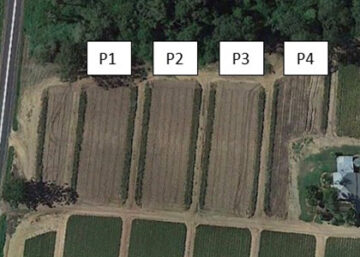

This demonstration trial compared boom spray operations using precision application methods against more traditional non-precision application methods. It includes economic and agronomics analysis.

OBJECTIVE

To develop and evaluate precision spraying in pineapples to improve fertiliser and pesticide efficiency and reduce off-farm deposition of these chemicals.

Specifically:

- Improve the application efficiency of foliar fertilisers and pesticides particularly during early growth stages when traditional broadacre boom spray equipment wastes product on non-target areas such as the inter-row and sides of the bed.

- Direct product to the target areas by only applying it over the plant rows.

- Show how traditional boom sprayers can be modified for a relatively low cost to reduce the amount of chemicals and fertilisers needed.

- Reduce the amount of fertilisers and chemicals applied to non-crop areas such as headlands and drains by giving the spray operator the ability to independently control different sections of the boom.